OVALJET COMBINES THE BEST PRACTICES OF SCREEN PRINTING AND DIRECT TO GARMENT PRINTING.

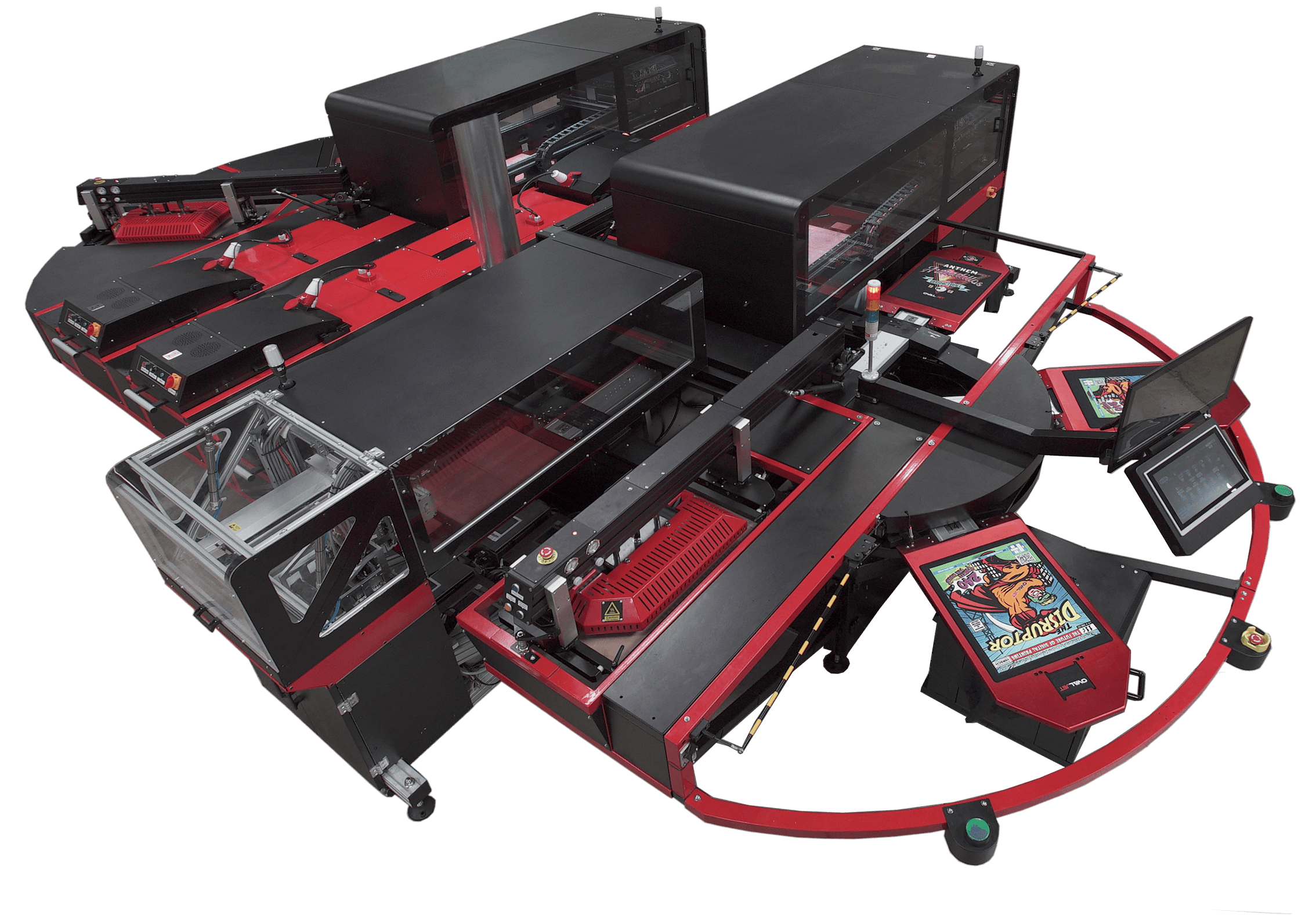

OvalJet’s closed loop technology moves each garment through a carousel of 14 automated stations that prepare and print garments in one smooth motion. This allows a single operator to achieve full size, full color prints at unparalleled DTG speeds.

- Meet new customer demands for increased number of colors, increased number of orders with lower print volumes and personalization?

- Reduce your on-hand inventory of finished printed goods?

- Quickly replenish specific prints and sizes?

- Print on demand and eliminate work in process (WIP) altogether?

- Increase print speeds to 240+ prints per hour?

- Decrease labor costs and increase printing floor efficiencies?

- Provide branding for your customers with in-line neck label printing?

- Eliminate the labor and effort of off-line pre-treating?

- Increase efficiencies by printing different garment types, colors and sizes all in-line?

Learn how OvalJet boosts speeds up to 240

prints per hour, fastest in the DTG sector.

What would unmatched revenue

generation do for your business?

Learn how OvalJet boosts speeds up to 240

prints per hour, fastest in the DTG sector.

What would unmatched revenue

generation do for your business?

Hover Over The Ink Drops to Learn About The OvalJet

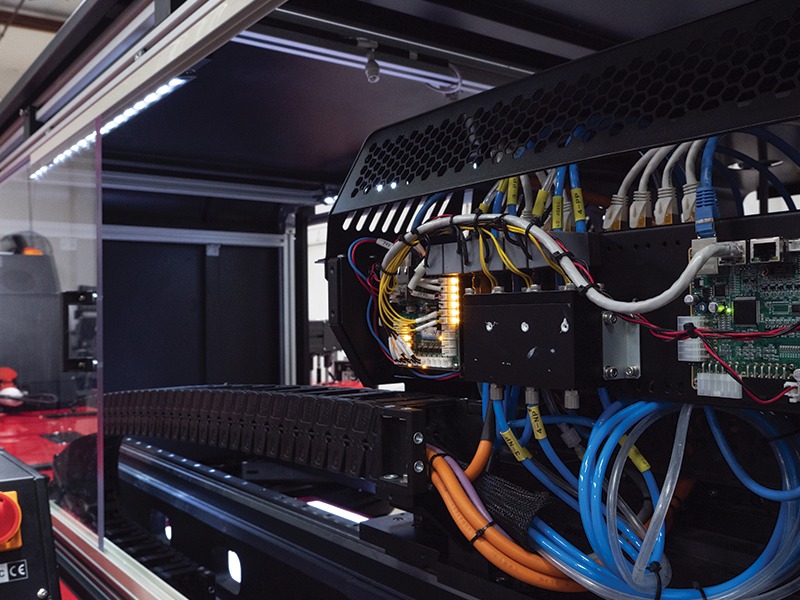

DIGITAL FOUNDATION

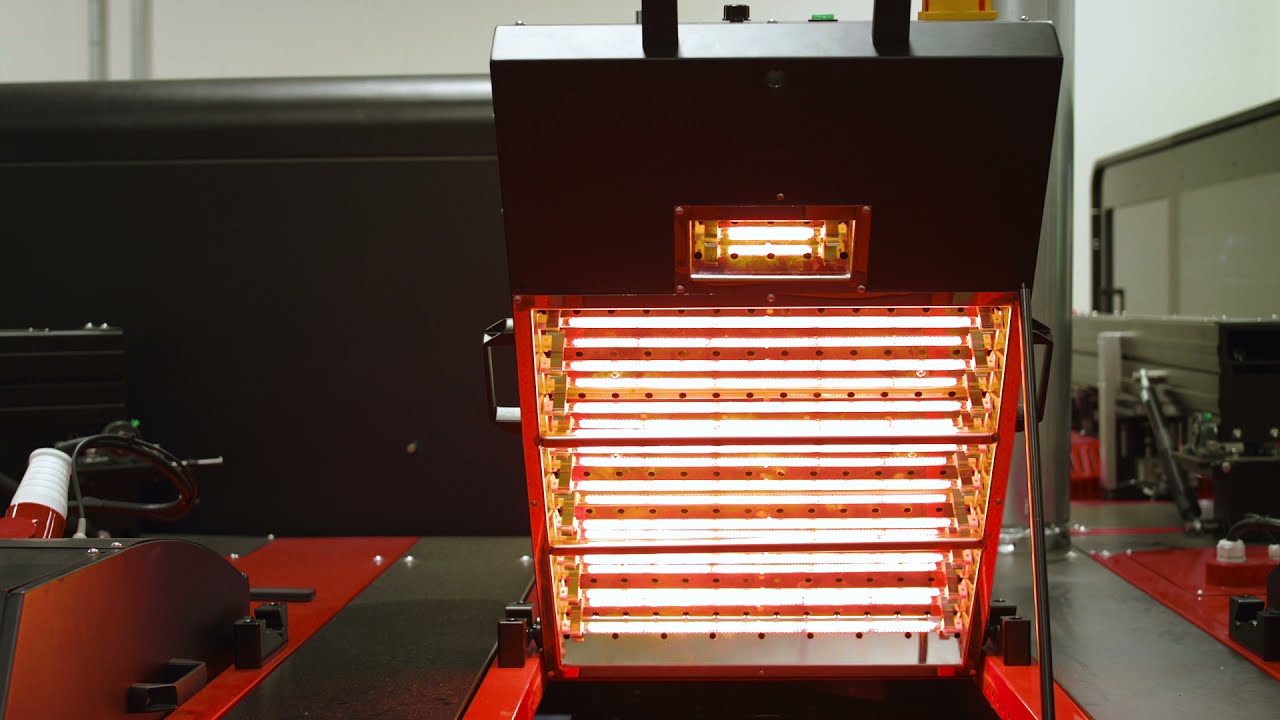

Our system is designed to increase efficiency and reduce the actions required to print a shirt. The digital foundation is able to prep blank garments straight from the box without slowing down the print heads or your team.SMART CURE

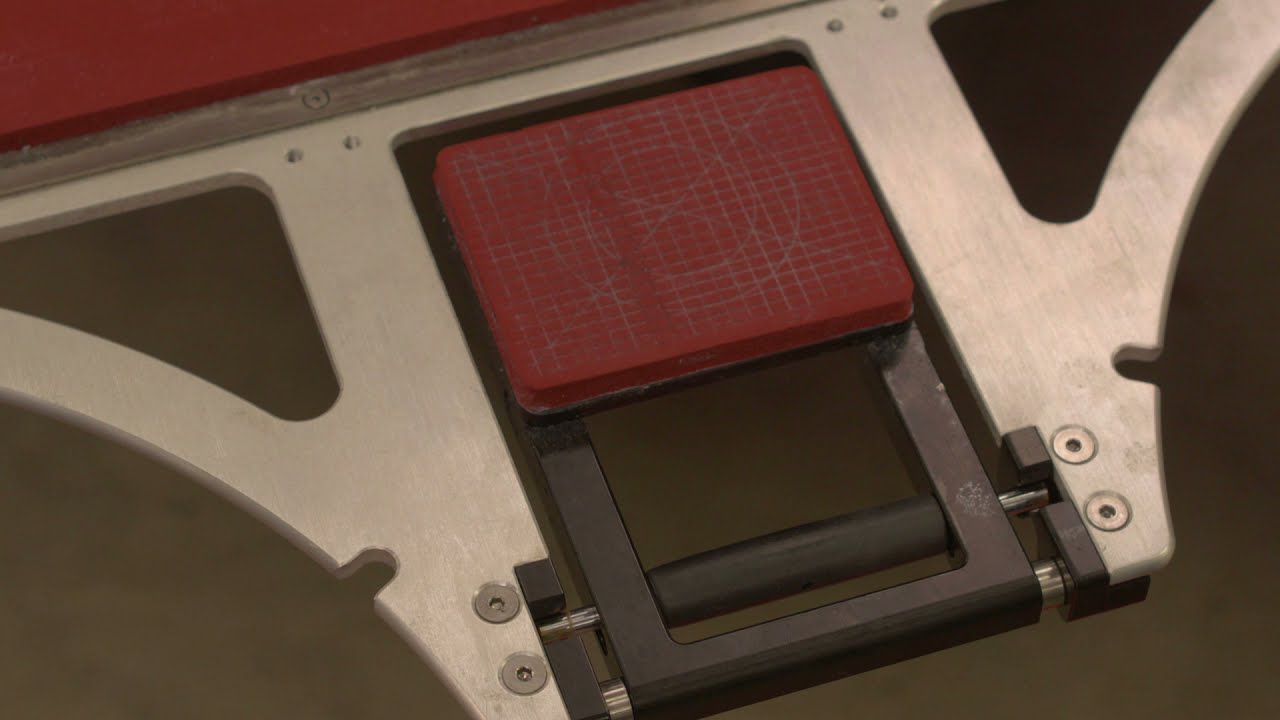

The Smart Cure system acts like a miniature oven for garments to slide under on their way to the print cabinet. In the few steps before they reach the printer, the foundation will be dry.SMART PRESS

Multiple Smart Press stations in the closed-loop are present to reduce fibrillation and create a flat, warm, wrinkle-free surface that is ready to receive ink.DIGITAL PRINT BOX

At the heart of every OvalJet is its temperature-controlled print cabinet. Just lift the black window panes or technician panels to easily access the components and print zone.PRINT HEAD TECHNOLOGY

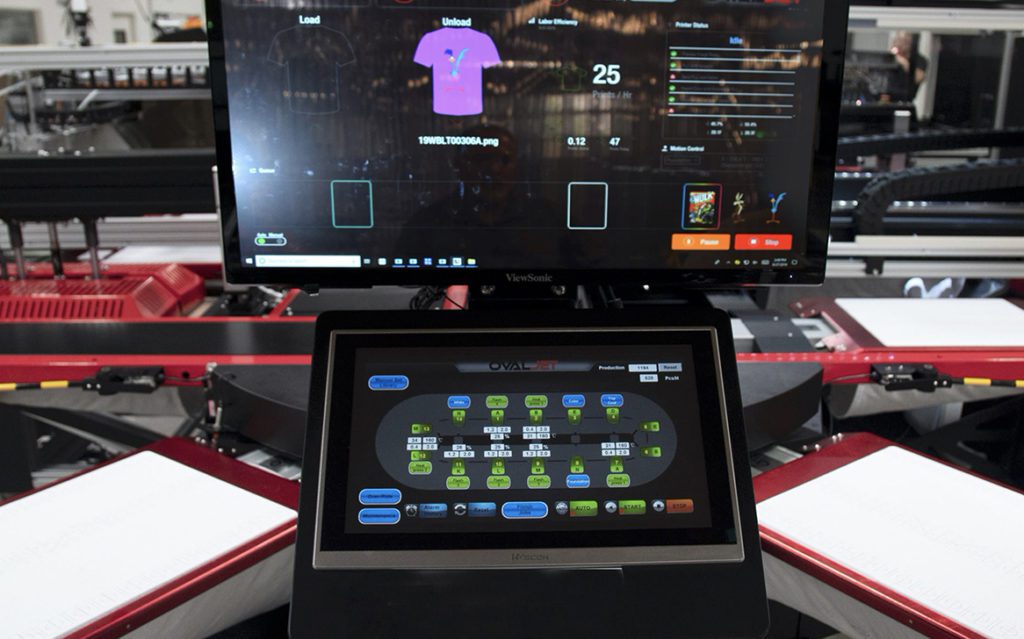

The OvalJet uses RICOH Gen 5 print heads for both stages of printing. First, a base layer of white is laid down to act as a canvas and make bright colors pop. After another pass of Smart Cure and Smart Press, millions of dropplets of CMYKRG ink are patterned over the garment to create your image.OPERATOR CONTROL SUITE

Our operator station gives one employee everything they need to run the OvalJet with efficiency. Garments are scanned on the fly, with dynamic settings applied to each garment.FULL SIZE, FULL COLOR

up to 240

PRINTS PER HOUR

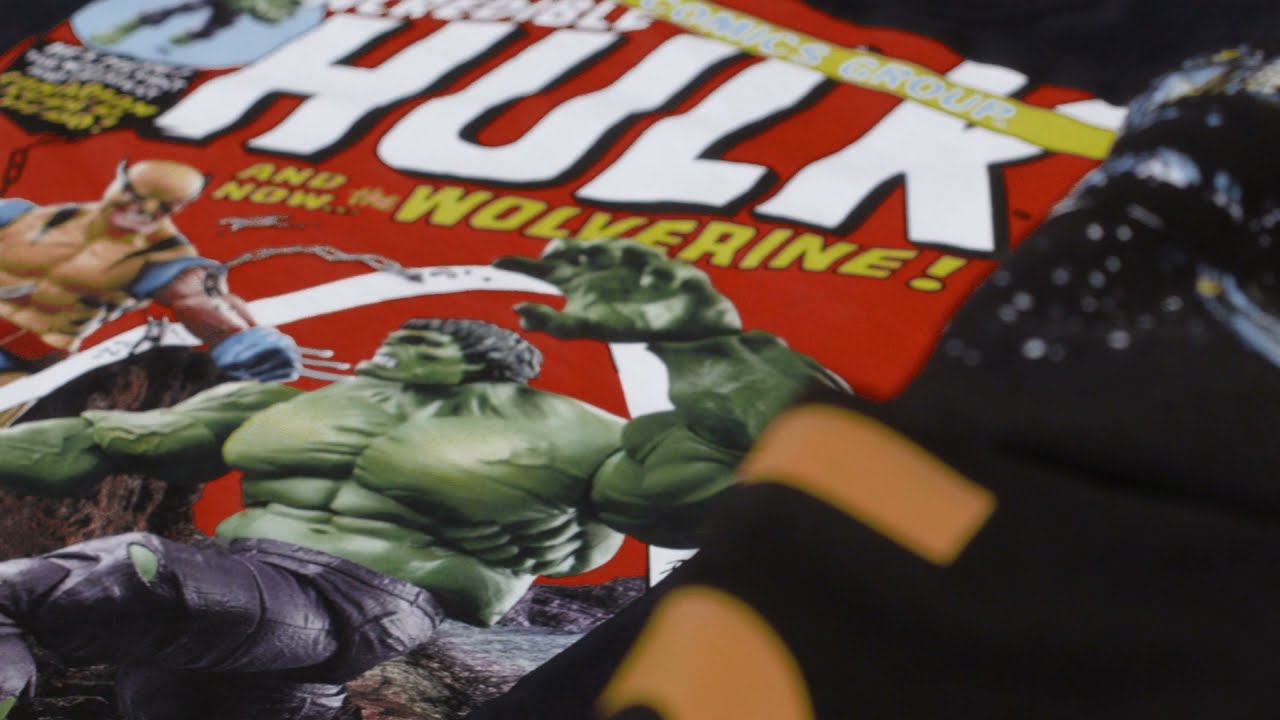

Superior Print Quality

The OvalJet print quality is superior to any other high speed DTG printer. Dedicated white and color print cabinets employ Ricoh Gen5 printheads and deliver the highest print resolution and best gradations on the market. Our proprietary 7 color ink set, CMYK+R+G+White, is formulated to print the largest color gamut, maximized white opacity and closest PMS color matching possible.

Whether you are printing photo realistic or illustrative artwork, the OvalJet high speed DTG printer delivers best-in-class print results.

Fastest Print Speed

OvalJet’s multi-pallet oval design enables a single operator to achieve full size, full color prints at unparalleled DTG speeds of 240 prints per hour. Each pallet has the “quick pallet release” feature enabling the operator to easily change pallets and run different styles, fabrics and colors in the same print run. The in-line digital foundation and the in-line neck label printing eliminate similar off-line processes, reducing excess labor and potential for errors.

The OvalJet was designed by DTG operators, for DTG operators, with speed and efficiency in mind and delivers the fastest print speeds in the industry.

Lowest operating cost

The OvalJet high speed DTG printer uses a proprietary set of inks, manufactured in the USA, and is the lowest cost per liter of any other DTG ink. These savings combined with the greatest number of prints per hour, reduced labor costs by eliminating operators and off-line processes like pre-treat and neck labeling, make the OvalJet the lowest operating cost in the industry-lowest cost per print, lowest labor cost, lowest cost per square foot of real estate.

The bottom line is the OvalJet equates to the lowest operating cost and contributes the most to your bottom line.

In-line Neck Printing

- Patented in-line process

- Branded Variable Printing

- Mass Customization

- No Screen Setups

- No Additional or offline handling

- Enables Custom Branding

- Maintain Print Speeds

Turbine Enterprise Software

- Robust Inventory Management

- Mobile Picking App

- Scan to Print

- Integrated Production RIP

- Quality Management

- Integrated Shipping

- Custom Handling

More OvalJet Action

SPOTLIGHTS ON THE OVALJET

Quick Release Pallets

Simple quick release pallet design securely attaches for perfect registration. Able to load different sizes inline for standard and women’s sizes.

Head Height Sensor

Measures garment profile automatically adjusting printhead height. Ensures optimal print quality while avoiding printhead strikes.

Inline Neck Printing

100% Digital variable printing with no screen setups or offline handling. Patented process enables complete branding with color labels.

Safety Switches

Multiple safety switches integrated throughout OvalJet. Pallet detection and safety bars prevent accidental cycling.

Digital Color

6-color configuration is standard (CMYK+R+G) to maximize color gamut and print range. High resolution Ricoh Gen 5 Printheads with 7-21 picolitre drop size.

Smart Press

Multistage fiber matt down. Highly durable modular design. Enables appropriate settings for each garment type.

Smart Cure

Multistage smart cure with variable settings of duration and intensity. Precisely dries foundation and white layers with a modular design.

THE OVALJET PRINT PROCESS

HEAR A TESTIMONY AND WATCH THE MACHINE IN ACTION

The History of the OvalJet

BUILDING AN INDUSTRIAL PRINTER